1. Project Summary

Western Health (WH) is undertaking an asset management transformation program with the aim to uplift systems, technologies, and people capabilities to meet evolving healthcare demands and ensure quality patient outcomes. The Maintenance Strategy Review and Optimisation (MSRO) project focused on generating optimal asset maintenance programs that aim to optimise cost, minimise risk of unplanned failures, and enhance equipment availability.

WH led this journey by collaborating with maintenance contractors and professional services to change the ways of working in the organisation, where the project becomes an embedded process for ongoing benefits realisation and best practice asset management.

2. Project Description

Project Objective and Scope

The MSRO project commenced in March 2022, beginning with WH’s Sunshine Hospital as the pilot. Their engineering services were evaluated, approximately 50 asset types, and targeting 24 asset types for inclusion. The aim was to undertake the MSRO process for Sunshine with the support of an external consultant to enable capability uplift of WH personnel as well as the use of asset management best practice in the process. The next stage was to replicate the process at Williamstown hospital to ensure its repeatability and to identify the required information for each site to adapt it appropriately. Ultimately this would be replicated across the remaining WH sites and integrated with the roll out of an enterprise asset information management system (AIMS).

Maintenance management at WH is delivered through a combination of in-house and contracted maintenance, with contractors involved in the delivery of preventative and reactive maintenance activities. Therefore, involving them in this process was critical to this success not only for their subject matter expertise (SME) but also to shift their approach towards a continuous improvement mindset.

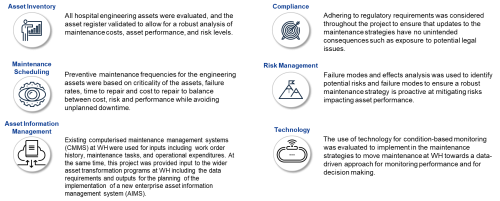

Best practice asset management principles

The MSRO project used a streamlined Reliability Centred Maintenance (RCM) approach while maintaining a line of sight with WH’s organisational objectives, ensuring delivery of quality patient care, and managing costs effectively. This was done by the following best practice principles:

Project Details

Overall, 24 asset types were evaluated, involving engagement with 29 contractors and 3850 assets in total across Sunshine and Williamstown.

Data validation

In the first step in the project, data validation was undertaken to:

- Extract WH’s asset register, including understanding the quantity of assets by asset type and the associated responsible contractors.

- Understand availability of information in the CMMS.

- Extract maintenance tasks and current strategy, frequency of preventive maintenance activities (internal and external) and associated costs.

- Extract failure history including work order history and associated cost of repairs.

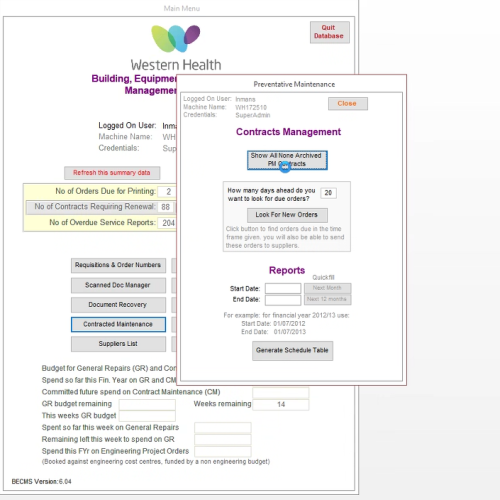

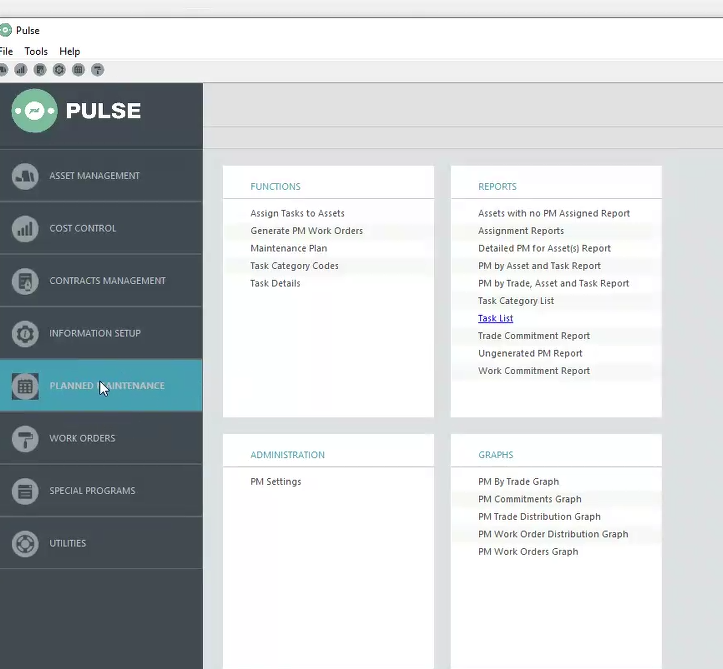

A challenge in undertaking this included that WH uses two systems, a CMMS for internal work orders and another for external contractors. The learnings and limitations observed out of this were taken into consideration for the requirements analysis for the development of the AIMS project.

| BECMS (External contractor CMMS) | PULSE (Internal work order CMMS) |

Contractor Workshops

Contractor workshops were held for each asset type and their responsible contractor in order to obtain their SME input for the operational and maintenance aspects of the assets. It also allowed for alignment with the contractors on WH’s transformation journey and continuous improvement mindset. The workshops were used to undertake the following:

- Failure modes and effects analysis (FMEA), identifying dominant failure modes and the effects on WH operations.

- Discussion on current maintenance strategies, including tasks and frequencies, to understand how they address failure modes and take onboard their recommendations for improvements.

- Discussion on the mean time to repair (MTTR) and operational downtimes for dominant failures, highlighting the availability of spares availability, and the cost of reactive repairs.

This exercise revealed some opportunities for WH including better contractor management, gold plated or obsolete solutions, and equipment compliance issues that required addressing.

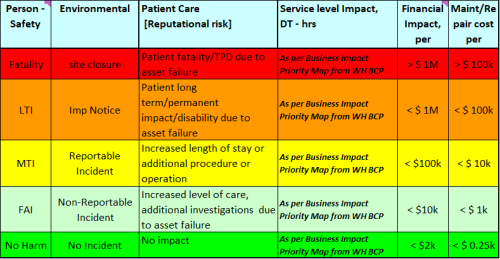

Criticality Analysis

Criticality analysis was then undertaken to understand the criticality of the assets and quantities; locations were also validated during this process. This improvement in asset information is important in informing the management of these assets for short-term operational purposes, as well as for long-term strategic planning.

Asset criticality was evaluated based on consequence factors aligning with the organisational risk matrix for WH and considering inputs such as the Business Continuity Plan (BCP) for service level impact in the hospital. This assessment was important in understanding the criticality of the assets to justify the balance between cost, risk and performance in the proposed optimal strategies.

One of the key challenges faced during the criticality analysis came from the quality of the data in the asset register, which included missing, mislocated, or unclear descriptions of the assets. This required data cleaning and validation to understand the operating context of each asset appropriately for criticality analysis. An ongoing work in WH is auditing and updating of engineering assets to ensure an accurate register is implemented into the future AIMS deployment.

Optimisation

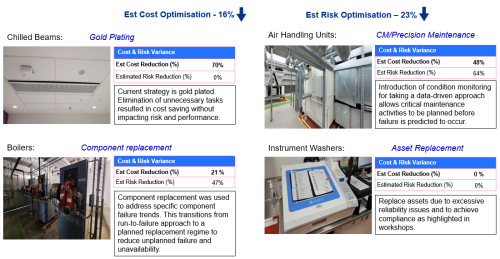

The strategies developed for each equipment type aimed to address the identified dominant failure modes, with maintenance activities at the optimal frequency to optimise risk and cost. The proposed strategies therefore were varied depending on the equipment criticality and maintainability assessments (to assess the feasibility of strategies on individual equipment). Where possible, the use technology to move towards condition-based monitoring was explored and implemented, alongside other approaches such as spares holding, planned replacement, or re-engineering.

Implementation

Effective strategy implementation and change management are important to ensure benefits realisation. At WH, this is being undertaken across the following domains:

Outcomes

The MSRO project has allowed for the improvement of asset availability, validation of the asset register, and development of a data-driven approach for decision-making with regards to maintenance and contract management. The implications involve savings on annual OPEX, while improving the reliability of equipment and reducing the risk of unplanned failures to result in better healthcare service delivery, through improved availability of hospital services and less disruption to clinical operations.

This project has allowed WH to implement a variety of strategies specific to the findings of each asset type, facilitating a transition from reactive decision-making to optimised and data-driven decision-making with respect to asset maintenance.

Project Management

The MSRO project adopted a co-sourced model between WH and KPMG, balancing the internal capabilities of WH with external expertise from KPMG to support the success of this project and its implementation into WH’s ongoing transformation. Some of the value-adding features from the project management methodology includes:

- The generation of artefacts for knowledge capture and transfer to the WH engineering services team.

- Tracking of program progress by activities and expected benefits to assist in quantifying the effort and value for business cases resulting from MSRO project such as purchasing of tools, contractor negotiation, and hiring of resources.

- Effective and collaborative stakeholder engagement across WH internal teams, KPMG as the delivery partner, and the 29 different contractor organisations.

Benefit / value to community

The MSRO project, through maintaining a line of sight with WH’s strategic goals was able to deliver benefits to the organisation including:

4. Opinion as to specific contribution made by the project team

Hannah Marsden and the Engineering Services team at WH embarked on this asset management transformation journey two years ago as Hannah became the Director Operations, Engineering Services. In that time, WH has initiated a program for this transformation including:

- MSRO Project: optimise and improve maintenance strategies with the aim to achieve 7% reduction in unplanned failures and annual spend on reactive repairs.

- AIMS business case: scope and approve the business case for an AMS software platform for delivery in 2022/23.

- Capital Asset Management Plan (CAMP): publish a data-driven and forward-looking CAMP process.

- Asset Register alignment: deliver a fully aligned Asset Master dataset, in the correct class hierarchy and matched to relevant failure records.

The leadership from WH to undertake this endeavour, combining their health service experience with that of industry and professional services, was key to the success of its outcomes. In a constrained healthcare environment, collaboration made a positive impact in sharing resources, knowledge, and the tools to improve healthcare delivery.

In the undertaking the MSRO Project, the team at Western Health supported in the following capacities:

| WH Team Member | Role |

| Hannah Marsden | Program Director |

| Masoud Goudarzi | Reliability Engineer and condition monitoring SME |

| Jon Patten | Facility Manager and SME, Sunshine Hospital |

| Sarah DeBono | Contract Manager and contractor point of contact |

| Frank Prestinenzi | Facility Manager and SME, Williamstown Hospital |

| Miguel Pinheiro | Maintenance Engineer |

As this was project delivered in a co-sourced model with KPMG, the following team from KPMG supported its delivery in the following capacities:

| KPMG Team Member | Role |

| Daniel Cato | Project Director |

| Ganesh Natarajan | Project Lead and SME |

| Omar ElSernagawy | Project Manager |

| Kathryn Lim | Asset management specialist |

Other key contributors to the project include:

| Key Contributor | Organisation |

| Penina Booker | Western Health |

| Angela Cannizzaro | Western Health |

| Faye Kis | Western Health |

| Matthew Turner | Western Health |

| Jenny Zhang | KPMG |

| John Seaman | KPMG |

| Stella Ulm | KPMG |

| Isabella Doan | KPMG |

| Rishi Wakle | KPMG |

5. General Comments

Department of Health Code Brown

Delivering the MSRO while Western Health was under code brown as a result of COVID-19 pandemic pressures on the public health system was a key challenge. Appropriately identifying criticality of equipment requires the input of operations personnel such as clinical and nurse area representation. This was mitigated as follows:

- Criticality analysis was undertaken with engineering personnel, including the facility manager, contract manager, and reliability engineer

- A presentation and criticality analysis guide was delivered to operations personnel with representation from all impacted areas in a single session

- Criticality analysis was distributed for offline review by operations personnel with their respective areas and required input highlighted

- Feedback from operations personnel was considered to adjust the criticality analysis and the associated maintenance strategies

External CMMS Limitations

A main limitation to collecting maintenance history and failure information was the data quality of the external contractor CMMS. A combination of using the record type and the description were used to develop categories to use for data analysis. The record types indicated whether a purchase order is:

- Preventative maintenance

- Reactive maintenance

- Corrective maintenance

- Capital / projects work

Analysing the categories in conjunction with the dates and costs of the purchase orders allowed the team to understand frequency of reactive maintenance, cost of maintenance, and to use a common timeframe for comparison of the data across Western Health’s sites.